Cosmetic Manufacturing

1. Formulation and Development

In the initial stage of formulation and development, our research teams work to create a new formula or custom formulation. The formula is developed in our lab, using a combination of equipment and research and development expertise to ensure product diversification. Equipment for mixing and preparing small bulk batches is pivotal for scaling up production.

2. Batch Production

During batch production, equipment such as large mixers and reactors are used to manufacture cosmetics in bulk. This process is closely monitored for consistent quality and adherence to planned formulation specifics. Mixing, heating, and cooling processes are key to achieving the correct consistency and stability of the product.

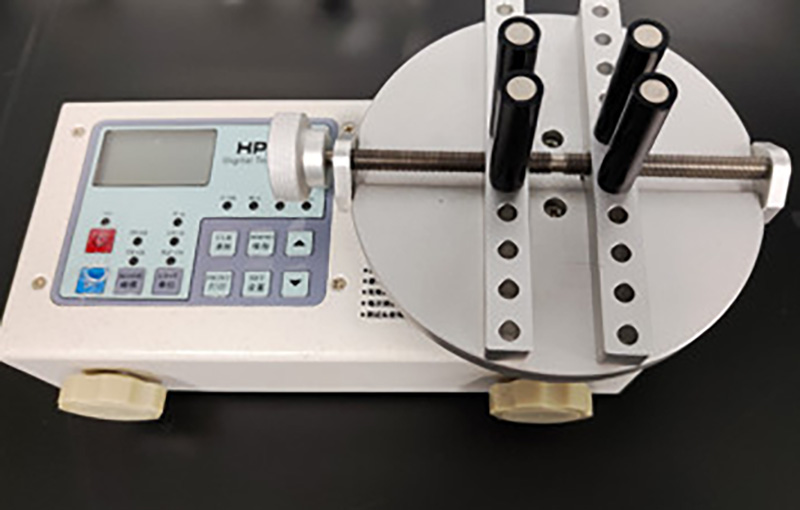

3. Quality Control

Every step of the production process is subject to rigorous quality checks. Chemists and microbiologists analyze ingredients, test product performance, and ensure adherence to strict safety and regulatory standards. Nothing gets past their watchful eyes!

4. Packaging and Labeling

Finally, the packaging and labeling process involves filling the products into tubes, bottles, or jars using automated filling systems. Packaging design plays a significant role in brand identity, and accurate labeling provides consumers with essential information. Shangyang self develops forward-looking and sustainable package design for our clients.